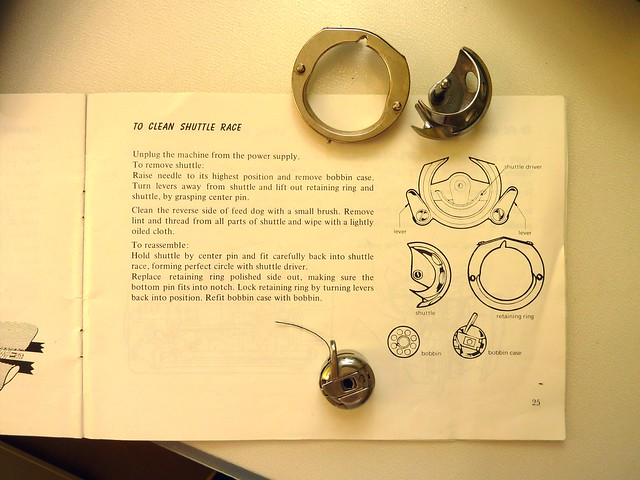

Cleaning the Shuttle Race

Page 25 from the Intruction Book for my *'Novum Deluxe IX' vintage sewing machine

Page 25 from the Intruction Book for my *'Novum Deluxe IX' vintage sewing machine

After the jinxed day that was last Friday (LOL!). I finally had time to sit down, clean and oil my favourite sewing machine.

If you recall, she kept tangling thread trapped underneath the feed dogs, and around the shuttle during sewing Hubby's new Ooo Rah Wallet. This meant the machine would stop in the middle of a stitch :(! And, the last time I detangled her the retaining ring and shuttle fell out when I accidentally knocked them as I removed the bobbin and case to get a clear view of the tangling.

I kept putting the parts back in correctly (or so I thought): shuttle, retaining ring, then bobbin in it's case. But the machine wouldn't move the needle up/down. It would go down and stay down and not budge. I figured I'd screwed-up the timing or something repair-shop worthy (gulp!). So, after an 'ickle panic on that Friday I decided to go to bed and deal with it in the morning - things always look better in the morning right?

I managed to find the manual - which is now scanned to file for safe keeping too ;). In the first picture at the top above you can see what they say about cleaning the shuttle race section.Can you see in their diagram how they don't show you the position of the shuttle driver (the little banana-shaped thingie)? To slot the shuttle against it correctly (together they form a complete full circle-shape), the driver should be vertically positioned - and to the left-hand side. I had been slotting everything back together with it on the bottom (doh!).

So, I turned the hand wheel towards me, got shuttle driver positioned just right and put all the other parts back inside together - and bingo! The needle moves correctly again - PHEW!!

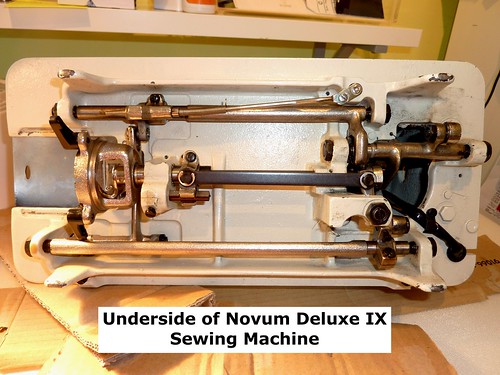

Here's a few photos of the insides – they’re here, so that if nothing else I can remember how to dis- and re-assemble things again for future. No more mis-aligning things for me please! I rested her on some bits of old cardboard box - 'cause she's heavy and the metal would scratch and damage my table top otherwise, plus it's good for catching any oil-spills too!

I cut up some small pieces of J-Cloth, because it's lint-free and won't leave deposits of loose fibres everywhere. After all, no point in cleaning out old lint and dirt to leave behind new clean-dirt is there? It'd defeat the point.

I also used some neat little tweezers I had - with a narrow/bent tip. I could fold up the small scraps of J-Cloth into a pointy triangle, dabbed some sewing machine oil onto them (not to much!) and really dig into all those nooks and crannies.

To be fair, she had very, very little dirt and barely any lint on her. With the tweezers there practically wasn't a spot I couldn't reach; and I got in and around the feed dogs nicely too.

I even found her serial number during the clean-up (I never noticed it before) - it's on the underside.

I even found her serial number during the clean-up (I never noticed it before) - it's on the underside.

After her oil up 'n' clean she was running smoother than before - and I managed to finish Hubby's wallet too.

TIP: I have a habit of knocking over things. So, I keep my small bottle of oil in a old clean plastic tub (an old Vanish Detergent tub 1.5kg size - because it's pretty tall). So, the oil lives in something that'll catch any drips/spills - and that tub lives hidden away inside the big drawers in my IKEA Expedit bookshelves. When I use the small bottle I pop it into a pencil pot on the table - that way I'm less likely to knock it over there too. I have a large bottle of oil I use to top up the small one - they live together in the plastic tub. The large bottle works out way cheaper per ml, but the small bottle (same size you get in the shops like John Lewis, etc.) are far easier to hold in your hands and manoeuvre around the machine parts that need the loving care and attention :)

Image Source: MySupermarket.co.uk

I use an empty Vanish Tub (1.5kg) to keep

my sewing machine oil bottle - so it's safe from spills!

*Sometimes also known as a 'Novum New Mark IX'

.jpg)

.jpg)

.jpg)

What a relief it was fixable! Good tip about the tweezers and j-cloth, thanks. Will give that a go next time I'm cleaning mine.

ReplyDeleteI know, I love that ol' machine :). Had her just over a year now, but I love that she's so straight forward and simple to use - just straight stitch or zig-zag (no fuss!)

DeleteP.S. I worked out that I can always wash-out the J-cloth scraps for use next time instead of throwing them away. I can throw them in a lingerie/delicates net-bag in the washing machine (along with a normal wash-load). Or... still in the bag (to make handling easier), add a dollop of washing-up liquid to cut through the oil/grease + wash them in the sink. I'm going to make a small pile of the J-Cloth scraps so I always have them on hand when I need them.

Claire...great job! We do a bit of our own maintenance and repair to the machines in my Studio...but only the mechanical ones. It's amazing what some oil, machine grease, and a cleaning will do for a machine. I swear I hear mine "sigh with content" when they've been cleaned/oiled :)

ReplyDelete(btw, did you see my answer to your question about rotating shirt darts...in a comment below yours on my recent pattern drafting post?)

Hi Pam!

DeleteThank you - and yes I saw your answer to my query on shoulder-darts (just posted a reply here). :)